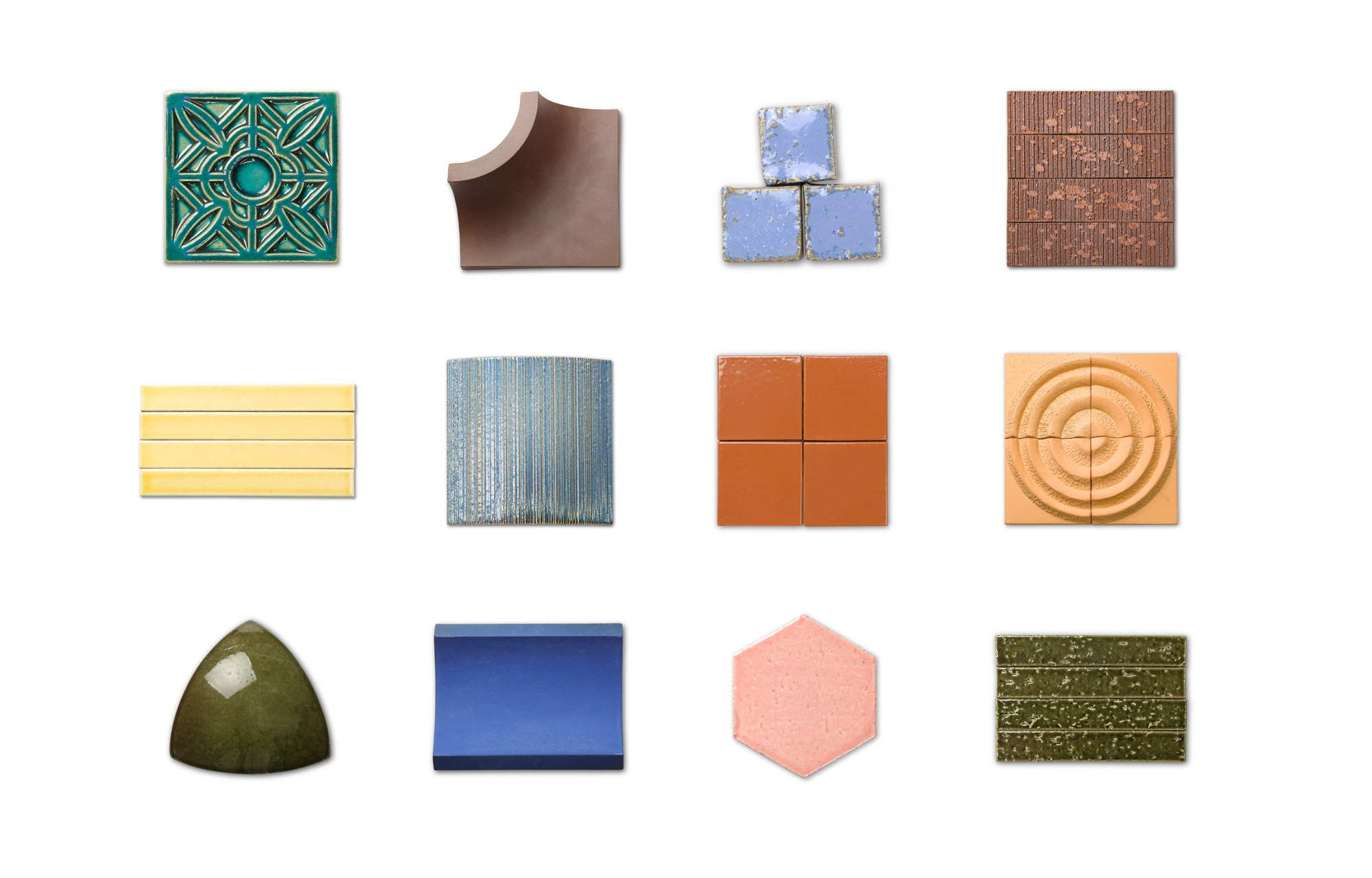

Bespoke tiles made using a blend of custom and traditional techniques.

In the southern area of Gifu Prefecture, central Japan, the soil contains mineral-rich clay. More than a thousand of years ago, a thriving ceramics industry emerged in this side of the country, including in what is now known as the city of Tajimi. The early twentieth century marked the birth of large-scale tile manufacturing in the area. Today, Tajimi accounts for around 90% of the tile production. While most of the companies that operate here use mass production techniques, some workshops and specialized companies focus on a blend of custom and traditional crafting methods to produce high-quality tiles. Tajimi Custom Tiles is one of them.

Launched by the X’S Corporation, a company founded in 1994 by Masashi Kasai, Tajimi Custom Tiles produces bespoke designs under the creative direction of David Glaettli. Born in Switzerland, he studied industrial design in Milan and Lausanne. After moving to Japan in 2008, he established Glaettli Design Direction Ltd. and started working as a creative director for Karimoku New Standard, Sumida Contemporary, and as a design director for 2016/ Arita. David Glaettli’s belief in the importance of high-quality tiles in architectural spaces and his support of local crafts and workshops have strongly influenced Tajimi Custom Tiles’ approach to design.

Celebrating Japanese ceramic traditions.

The company produces bespoke tiles for international architects and interior designers both in its in-house laboratory and by collaborating with local manufacturers. Proprietary and traditional techniques of glazing and firing allow the company to create custom tiles in any size, shape, and color. These specialized methods also allow artisans to give the tiles a range of finishes. The company’s tile makers employ a variety of techniques to achieve the warm, handmade look of Tajimi Custom Tiles.

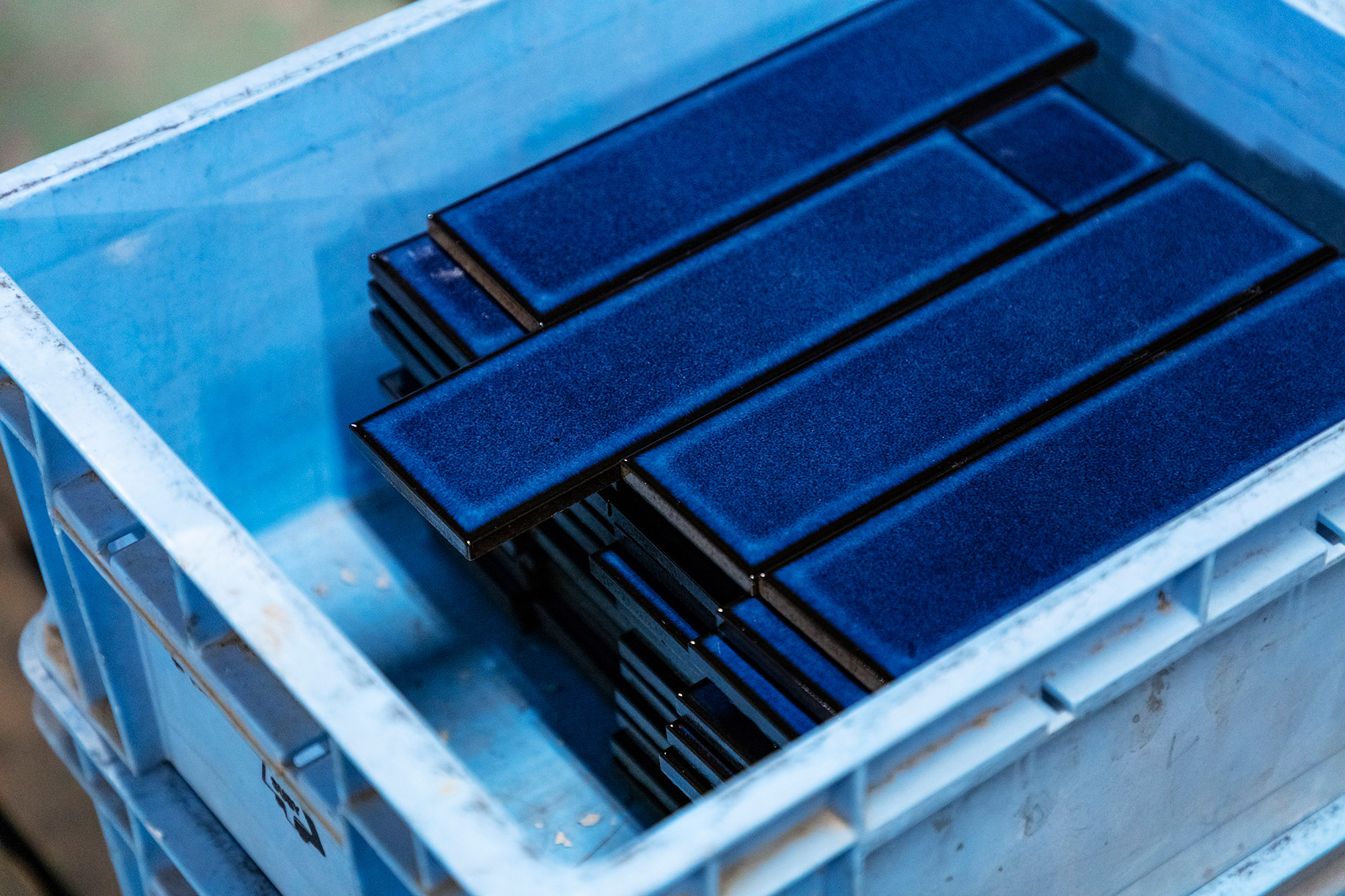

While most tiles worldwide are mass-produced and fired in roller heath kilns, the brand uses tunnel and shuttle kilns. Fluctuating temperatures and long firing times also allow the artisans to create tiles with variations in color and texture. To produce tiles with striking effects, the craftsmen also use a reduction firing technique, along with special glazes. Tajimi Custom Tiles uses four main techniques in the manufacturing process.

Highly automated and efficient, the dry press method ensures a uniform, clean look. It’s also the most common method to produce tiles, worldwide. By contrast, the almost extinct wet press method requires extreme precision and skill. This technique produces one-of-a-kind tiles and suits custom designs in small runs. Clay extrusion is partially automated but produces tiles with a handmade look. Finally, pressure molding suits small to medium runs; this method allows artisans to reproduce intricate patterns with an impressive level of detail.

A series of experimental objects created by award-winning designers.

Two collaborations with award-winning designers Kwangho Lee and Max Lamb marked the company’s launch in 2018. Both designers received the same brief, to create experimental objects using traditional and local materials and techniques. For the Tide series, Kwangho Lee took inspiration from the clay extrusion method. He made modular objects which allow horizontal and vertical stacking. Aligning the modules created a loop pattern that reminds of knitted fabric, an important motif in the designer’s work.

Likewise, Max Lamb used modular design as a base for his Working Tile series. Made with pressure molding, his 3-dimensional tiles come together in diverse compositions to create objects like benches, tables, or vases. Special glazes and earthy clay allowed the designer to produce intriguing tile colors.

Tajimi Custom Tiles will showcase a collection of innovative ceramic products to celebrate the brand’s global launch during Milan Design Week. Apart from large-scale objects created by Max Lamb and Kwangho Lee, the company will also display new designs by Ronan & Erwan Buroullec. This year, the event lasts from 7 to 12 June 2022. You can admire the brand’s experimental designs at Gallery Assab One, Via Privata Assab 1, 20132 Milan. Photography© Tajimi Custom Tiles.